Product overview

Oil-free vacuum pumps are specifically designed for industrial automation and smart manufacturing, suitable for various cleanrooms and high-purity environments. Utilizing dry technology without relying on oil lubrication, these pumps completely avoid the generation of contaminants during operation, making them particularly ideal for applications in semiconductor and precision electronics manufacturing, as well as industrial production environments where vacuum purity is of utmost importance. As smart manufacturing becomes more widespread, the stability and low maintenance requirements of oil-free vacuum pumps have made them essential equipment on automated production lines, helping to enhance production efficiency and reduce maintenance costs.

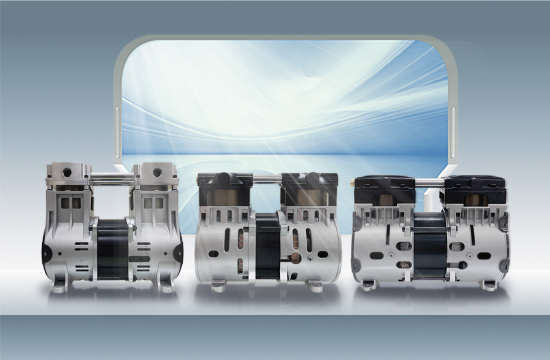

Oil-free air compressors offer high-purity compressed air, making them widely used in the medical, biotech, and laboratory sectors. In these industries, compressed air directly interacts with products or processes, so the purity of the air is critical for product quality and the operational environment. Oil-free air compressors ensure that the compressed air is free from oil, preventing any potential cross-contamination, which is especially important in applications such as oxygen generators, hyperbaric chambers, medical device manufacturing, and pharmaceutical production. Additionally, the oil-free design significantly reduces the need for maintenance during operation, ensuring long-term stable performance.

Oil-type vacuum pumps are indispensable components in food packaging, food processing, and rubber/plastic molding equipment. These pumps use oil as a lubrication and sealing medium, providing higher vacuum levels and stable operational performance, suitable for production environments requiring higher vacuum degrees. For example, in the food packaging industry, vacuum packaging machines rely on stable vacuum pumps to ensure the sealing of packages, thus extending the shelf life of food. In the rubber and plastic molding process, oil-type pumps handle high temperatures and demanding environmental conditions, ensuring process quality.

The high airflow and pressure capabilities of industrial blowers make them key equipment in industries such as printing machinery, plastic extrusion, wastewater treatment, and textiles. These blowers are commonly used for conveying gases, compressing air, or providing suction power. The printing industry requires stable airflow to ensure print quality, while wastewater treatment plants rely on blowers for oxygen delivery, promoting efficient wastewater treatment processes. In industries like textiles and plastic extrusion, industrial blowers ensure stable airflow during production, effectively boosting production efficiency.

Vacuum accessories include vacuum filters, pressure-regulating filters, FRL (Filter-Regulator-Lubricator) combinations, and oil mist filters, playing a critical role in vacuum and air systems, particularly in air quality management. Vacuum filters effectively prevent dust particles from entering the vacuum system, maintaining system stability; pressure-regulating filters allow for precise control of air pressure, enhancing operational accuracy; the FRL combination ensures overall operational efficiency of the air supply system; and oil mist filters remove oil mist, extending the lifespan and performance of the system. These accessories are suitable for various vacuum and air systems.

Ready to be used immediately by the person who is buying. UNi-CROWN’s product line includes a wide range of pumps, such as model air compressors, inflators, electric vacuum aspirators, and oxygen generators. These products are used in various domestic and industrial settings. For instance, model air compressors and inflators are widely applied in DIY projects, automotive maintenance, and more, while vacuum aspirators can be customized according to specific needs. All these products are plug-and-play, ready to meet your immediate requirements.